Continuous improvement thrives on a strong foundation, and for many organizations, especially those familiar with the Toyota Production System (TPS) and lean practices, the blueprint for success is rooted in “Standard Work” sometimes referred to as ‘work standardization’ or SOP its purpose is to provide a reliable framework for problem-solving, stability, and of course, kaizen.

Table of Contents

ToggleEssence of Standard Work: The proven method to deliver a product or service efficiently

Think of standard work or SOP (Standard Operating Procedure) as your formula for triumph. The term might have evolved over the years, but its core concept harkens back to Toyota’s approach. In a well-executed system, this formula is equivalent to a musical score that guides every player.

There are different methods to encapsulate standardized work, including:

- Guided manuals & Procedures

- A systematic 8-step approach

- Tutorial videos

- Focused learning modules

- TWI task guidelines

Regardless of the method employed, the end goal is consistent: establishing a robust platform for kaizen and problem-solving.

Challenges in operational consistency, fostering a culture of improvement, or robust problem-solving might be traced back to ineffective utilization or understanding of standard work.

Building Blocks of Kaizen

Often, the true essence of standard work gets overshadowed. The objective is to craft a method so solid that it becomes the industry gold standard. This involves three foundational steps:

- Process Equilibrium: This involves ensuring that the 4M’s (manpower, machinery, materials, methodology) are in harmony. This means mitigating issues like machine failures, staffing concerns, training inadequacies, or discrepancies in approach.

- Process Codification: After achieving equilibrium, the focus shifts to documenting the best proven method. This serves as a benchmark for future improvements.

- Process Preservation: It’s futile to codify a process if it’s not upheld. Organizational practices must be adjusted to maintain the improvements and standards achieved.

It’s paramount to recognize that any kaizen activity should ideally culminate in an updated standard work.

Journey up the Kaizen Slope

As illustrated, the mantra to ensuring improvements are lasting is to stabilize, codify, and preserve the processes. Without mastering these steps, the journey of improvement is fraught with risks of regression.

Taiichi Ohno, a pioneer of the Toyota Production System, emphasized that standard work forms the bedrock of kaizen. It’s the yardstick against which advancements are gauged. He famously noted, “Kaizen is unattainable without benchmarks.”

Crafting the Perfect Formula!

The process of standardizing work is akin to crafting a beloved recipe, say, your grandmother’s cherished chocolate chip cookies. Recipes are not designed to curtail innovation but to replicate success and act as a foundation for tweaks. The philosophy behind standard work mirrors this!

An efficient standard encompasses:

- Task sequence

- Event chronology

- Resources (manpower, machines, materials)

- Arrangement of resources

- All other vital details

While many firms have procedures in place, a successful recipe-like approach to standard work remains an elusive dream for many.

Classic Approach to Standard Work

Traditional standardized work, as seen in organizations like Toyota, emphasizes:

- Takt Time: The time dedicated to product creation, aligning with customer requirements and aimed at curbing excess production.

- Task Flow: The precise set of actions to accomplish tasks.

- Inventory Norms: These synchronize all parties involved and keep overproduction in check.

Creating standards for these elements typically involves a methodical approach, incorporating various tools and worksheets.

However, it’s crucial to realize that besides this “classic” methodology, there are innovative alternatives worthy of exploration.

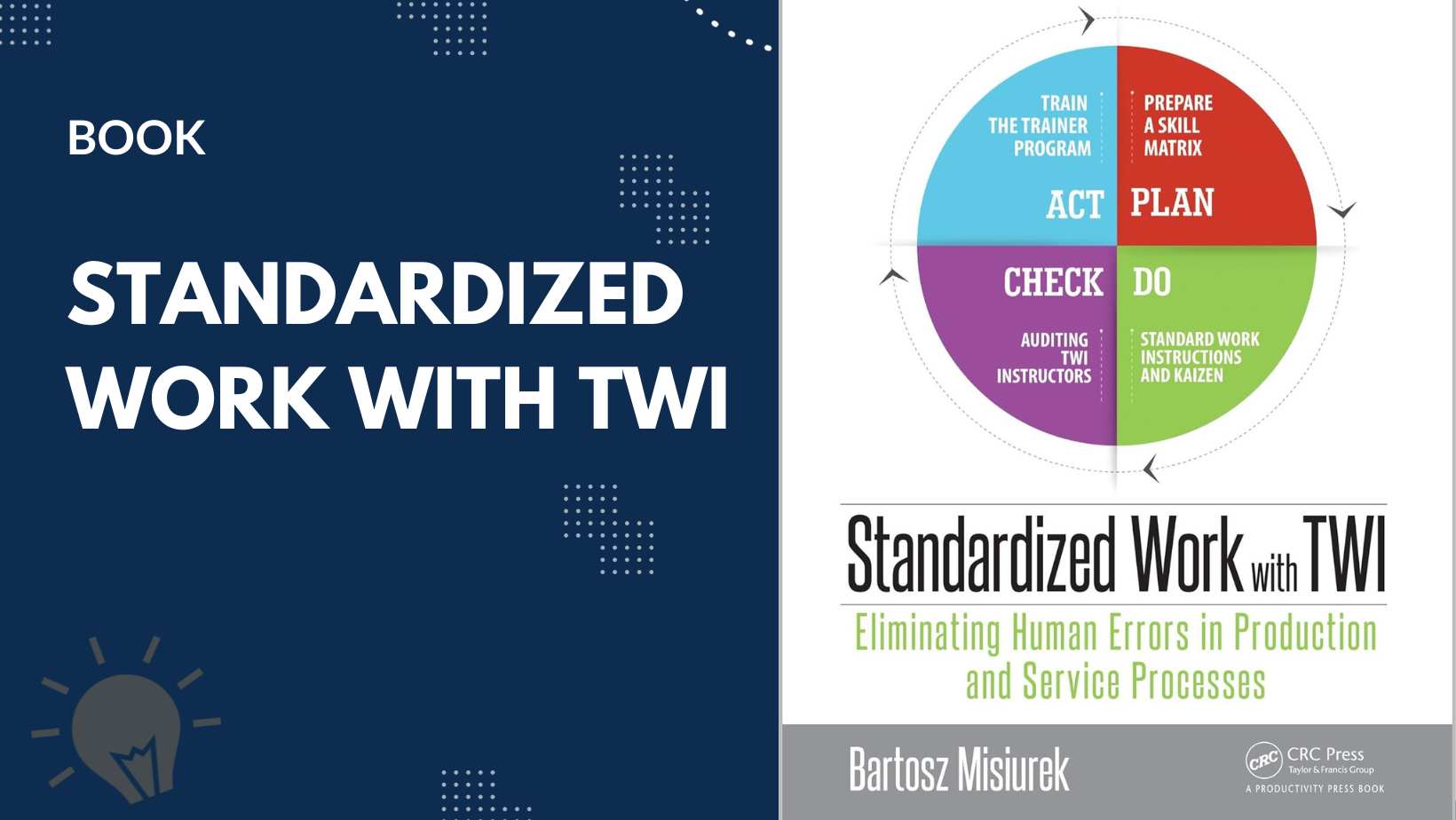

For instance, Training Within Industry (TWI) focuses on task guidelines as a pivotal step post-traditional standard work. It has a rich history dating back to World War II and has been a crucial element of the Toyota Production System.

New-Age Methods for Standard Work

Modern methods are broadening the horizons of standard work. Here are some contemporary approaches:

- Digital Demonstrations: Companies like FastCap have leveraged videos for training, standard work, and showcasing improvements.

- 8-Step Module: Some firms prefer a streamlined 8-step pictorial guide, supplemented with concise text.

- Guided Manuals: Regulatory frameworks like ISO 9001 have popularized detailed work instructions across sectors.

- Focused Learning Units: These single-page directives are invaluable for equipment handling and maintenance, among other areas.

In summary, the blueprint for continuous improvement is dynamic, evolving with time and innovations. However, the essence remains rooted in a solid foundation, built on the principles of standard work.

Best Software for Standard Work

The best software for Standard Work is characterized by its ability to streamline and simplify the creation, management, and execution of standardized procedures within an organization. Key features of such software include an intuitive user interface, robust customization options to tailor standard work templates to specific organizational needs, and the capability to easily update and distribute procedures across various departments. Additionally, top-tier standard work software often integrates with other enterprise systems, supports real-time collaboration and feedback, and offers detailed tracking and reporting functionalities to monitor adherence and identify areas for improvement. This type of software is essential for organizations looking to enhance efficiency, ensure consistency in operations, and maintain high-quality standards in their work processes.